On the planet of electronics, the value of PCB assembly can not be overstated. As gadgets become portable and increasingly complicated, the need for premium PCB assembly manufacturers has actually surged. Printed Circuit Boards, or PCBs, offer as the backbone of a lot of digital devices, supplying a system for the connection and functionality of various digital elements. When talking about PCB assembly, it is critical to comprehend not only the procedures involved yet likewise just how to select the best PCB assembly manufacturer to make sure that the final product satisfies the highest possible criteria of high quality and integrity.

The PCB assembly procedure contains a number of vital steps, including assembly, design, and prototyping. Designing a PCB includes developing a schematic layout that details how the numerous parts will get in touch with each various other. This is a vital step, as mistakes in the layout can cause defective products. As soon as the style is finalized, a model is usually created to check functionality. After strenuous testing and needed iterations on the model, production can start.

One crucial facet of PCB assembly is surface install innovation (SMT), a method that has actually reinvented the manufacturing process by allowing for the mounting of components directly onto the surface area of the PCB. An additional typical technique is through-hole technology, where components are inserted right into openings on the PCB and soldered in area.

When choosing a PCB assembly manufacturer, numerous factors need to be taken into consideration to make certain the best feasible end result. A credible manufacturer should have a tested track document of delivering top notch items and excellent customer solution.

Another important facet to examine is the manufacturer's abilities and technology. The very best PCB assembly manufacturers stay at the center of technology, using innovative manufacturing processes and devices. The most recent machinery can substantially boost the precision and speed of PCB assembly, eventually making certain a better final result. The capacity to handle both high-volume and low-volume manufacturing runs is additionally a beneficial attribute, as it offers flexibility based on your specific needs. Makers that invest in research and growth are extra likely to adopt innovative techniques that might benefit your project.

When picking a PCB assembly manufacturer, expense is one more vital factor to consider. While the rate is a vital element, it should not be the single factor. A small cost usually comes with the expense of top quality, which can cause a host of problems later on. It is smart to acquire quotes from multiple makers and compare not simply the prices but additionally what is included in each quote. This can give quality as to where the value exists.

It is important to review timelines upfront and have a clear understanding of the manufacturer's capability to fulfill deadlines. Hold-ups in assembly can have plunging effects on product launches and supply chain monitoring, which can ultimately affect a business's success.

When an appropriate PCB assembly manufacturer has been chosen, the partnership must begin with open communication. Producers that are prepared to work carefully with clients to deal with issues or make enhancements demonstrate a reliable collaboration.

Quality control steps should be in area from the early phases of assembly, including inspections, screening, and verification procedures. Using automated optical examination (AOI) can assist catch flaws that may not be noticeable to the nude eye, while functional screening can confirm that the assembled PCB executes correctly in real-world problems.

As innovation advances, the landscape of PCB assembly production is changing. Patterns such as miniaturization, increased intricacy, and the demand for personalization are driving technologies in PCB design and assembly procedures. Technologies like 3D printing and laser direct imaging, together with products that permit versatile and rigid-flex circuits, are examples of how manufacturers are adjusting to these fads. Remaining upgraded on these growths enables a company to pick a PCB assembly manufacturer that doesn't simply fulfill existing demands yet is likewise gotten ready for future demands.

Sustainability is coming to be an increasingly crucial element of electronics producing. As organizations and customers alike become more environmentally mindful, working with a PCB assembly manufacturer that focuses on environmentally friendly procedures can enhance your brand's reputation. This can include using lead-free solder, reusing programs, and accountable waste management techniques.

Another crucial consideration when going over PCB assembly is the capacity for ongoing assistance and solution after the assembly is complete. A high quality manufacturer does not simply supply the set up PCB and leave; they ought to be available for assistance with any concerns that might arise post-delivery. Whether it's repairing, repair work, or upgrades, having a relied on partner that can offer recurring support can be invaluable in preserving the longevity and efficiency of electronic items.

Looking ahead, embracing technical advancements and promoting solid connections with PCB assembly producers will be crucial to doing well in the fast-evolving electronic devices landscape. The convergence of emerging innovations, consumer expectations, and sustainability will keep best pcba define the future of PCB assembly.

In verdict, navigating the globe of PCB assembly needs a comprehensive understanding of the production process, a critical technique to choosing the best PCB assembly manufacturer, and a dedication to quality and technology. Therefore, choosing to function with a reliable PCB assembly manufacturer is not simply a technical choice; it is a tactical organization option that can thrust a brand in the direction of long-lasting success.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Lucy Lawless Then & Now!

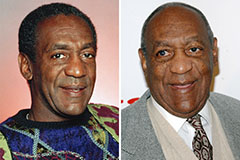

Lucy Lawless Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!